Challenging Conventions

We transform spaces with unique freeform site-specific installations that are both engineered and functional. We embrace sustainability and alternative building methods to create lightweight structures that enhance the experience of a location.

Studio Impossible Projects brings together the best of both worlds.

Drawing on their Dutch background, they strive to create designs that challenge the boundaries of what is achievable in the most efficient manner possible while their time in the Philippines has taught them to consider locally available materials, technology, and skill levels in their design and construction process.

As a result, Studio Impossible Projects’ approach combines innovation and practicality, resulting in awe-inspiring creations that transcend conventional design paradigms.

ABOUT US

Impossible Projects is a design studio whose practice is based in both the Netherlands and the Philippines.

We operate within the realm of architecture and art and our aim is to challenge the conventional notions of architecture and construction in order to create functional structures that blend into their surroundings and have a low environmental impact.

We continually research new materials and building methods taking into account locally available materials, technology and skill levels in order to achieve complex designs that are executed in the simplest and most direct way.

Studio Impossible Projects is spearheaded by Jasper Niens & Rick Atienza.

Jasper is an artist and researcher who in his practice developed algorithms and building techniques that allow him to build large-scale installations and structures.

With over two decades working in the global shipping industry, Rick has gained extensive knowledge in managing people and organisations in a cross-cultural setting.

Discovering their shared joy for building, they have dedicated their expertise to Studio Impossible Projects.

Founders of Studio Impossible Projects

WHAT WE DO

ART

Our practice draws its inspiration from the boundless possibilities in art. As such, S.I.P. also serves as the back office to support the art practice of Jasper.

This allows us to experiment and play with different materials, technologies and techniques.

BAMBOO

Bamboo is a remarkable natural building material and we hope to help elevate this material to its full potential using parametric design and digital fabrication.

Allowing us to further explore the true potential of a readily available and renewable material.

ARCHiTECTURE

Parametric design and fabrication solutions allow the ability to design buildings that are unique and innovative while using locally sourced renewable materials effectively.

We challenge ourselves to come up with simple and effective solutions for different aspects within an architectural context.

innovation

Our practice would not be possible if not for the broad spectrum of people with whom we work, collaborate and exchange ideas.

The cooperation with engineers, artists, artisans, and our own team all make our practice flourish because of these multi-cultural, multimedia and multi-faceted interactions.

In order to expand this space for creativity, we are inviting other like-minded individuals who can contribute in the field of art, engineering, architecture and bamboo to join us.

PROJECTS

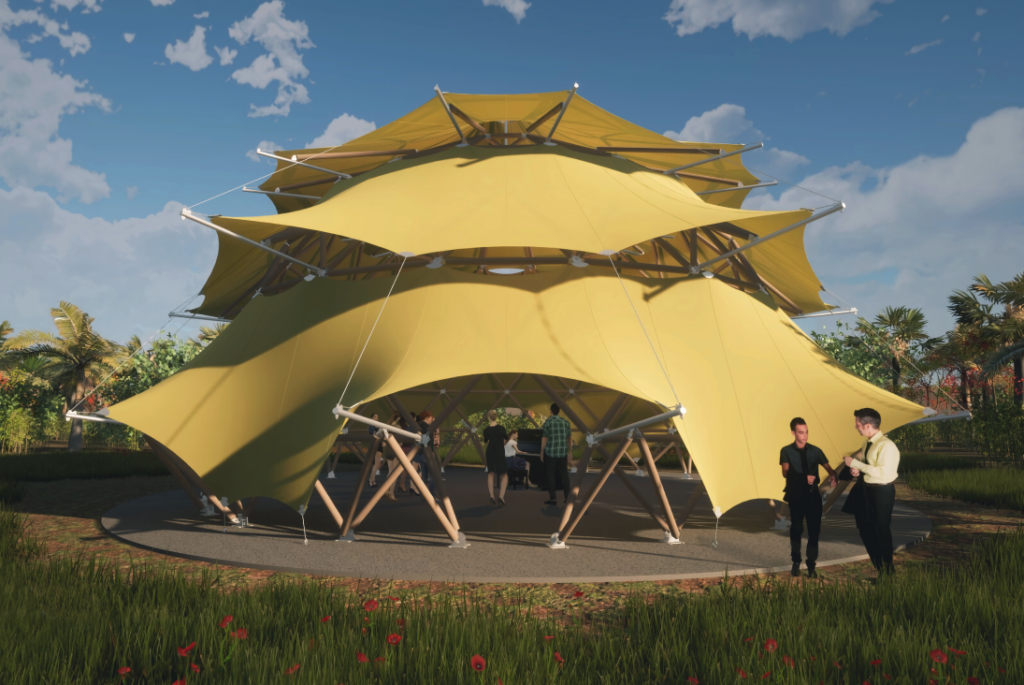

Banwag

A bamboo fabric dome commissioned for the Pablo Sarmiento Group in close proximity to the expected new government centre of the Bangsamoro. This is a place for people to congregate and serves as a symbol of peace between the Muslims, Christians and Lumads of the region.

Tensile Bamboo Shades

As the first iteration of its kind, the Santa Fe proves that it is possible to create a tensile shade utilising bamboo, fabric and stainless steel. The shade features marine grade fabric, treated bamboo and custom rigging adopted from the marine sailing industry.

Dragon Eggs

The ‘Dragons’ are two mirrored domes standing opposite to each other lengthwise conjoined by a tensile fabric, with a net usable area of 340m2, a footprint of 16 x 37 metres and a height of over 7 metres.

Dome Village - New Clark City

The Dome Village is a series of four dome-like structures linked by suspended bridges, and located in the River Park in New Clark City, Philippines.

CONTACT US

Inquiries

For any inquires, questions or commendations, please reach out to us through WhatsApp or fill out the following form:

Head Office:

Address

Pompstraat 44c, 3082 RT Rotterdam, The Netherlands

connect@impossibleprojects.net